Dierre’s Technical Service

Service at the Core: A Constantly Evolving Reality Aiming for a 3.0 Organization

Dierre's Technical Service (TS) comprises 45 nationwide operators, all coordinated by a central office acting as the system's beating heart. They ensure pre-and post-sales support throughout the supply chain to the end consumer. This service is crucial, as it is the vital link between the product and those involved: the manufacturers, the dealers who present it to the end consumer, and the installers.

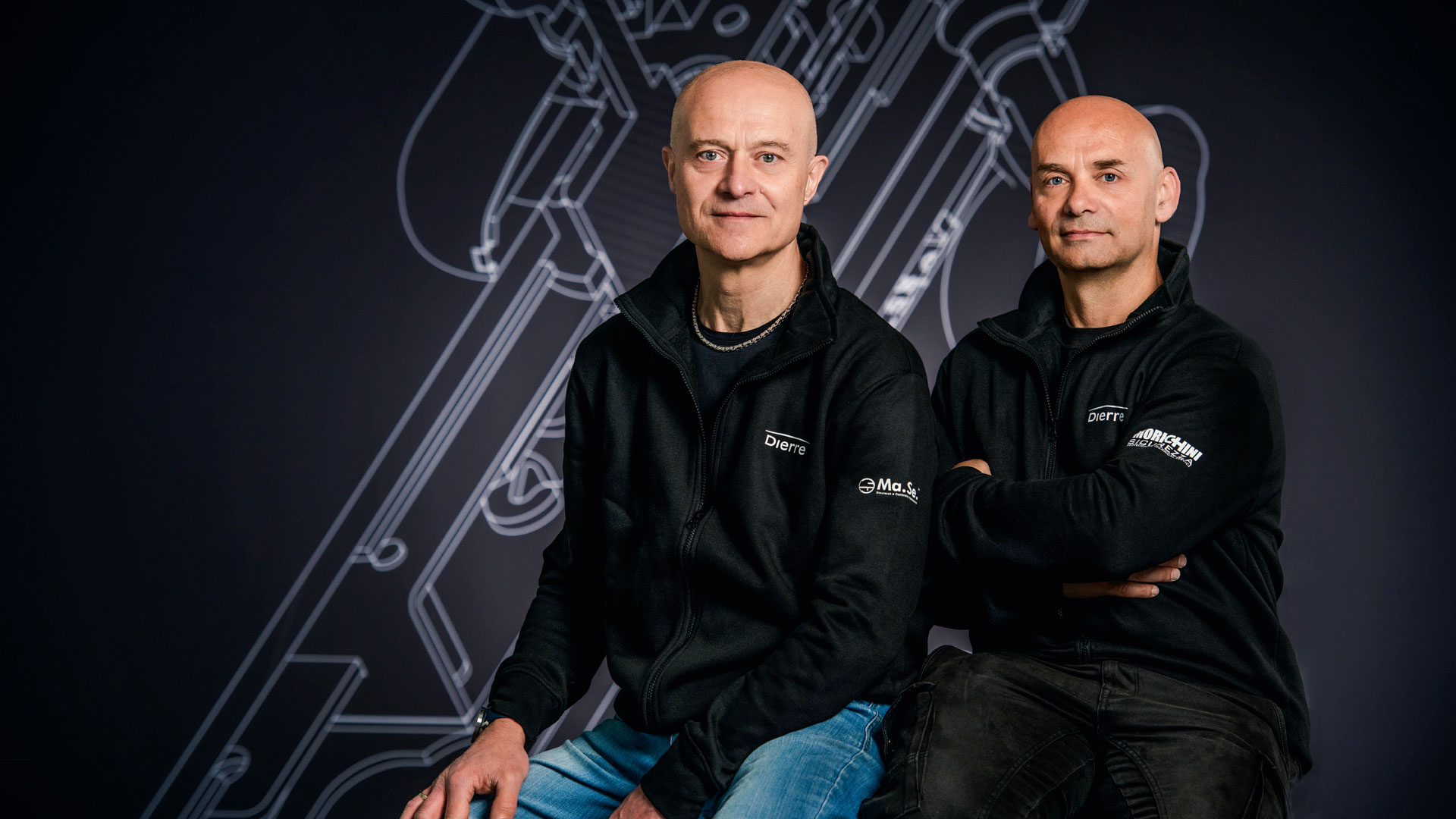

To enhance the Dierre brand, improve warranty and after-sales services, and streamline communication between the company and its network of technicians, the Technical Service is evolving towards a more fluid and efficient organizational model. A key factor in this transformation is the ongoing training of dealers and installers through the Dierre Academy and the addition of two new coordinators to improve communication between the company and the Technical Service network. Sergio Masè and Valerio Morichini are leading this complex organization and have extensive security experience. We interviewed them for their insights on the current state and the challenges ahead.

Dierre’s Technical Service (TS) comprises 45 nationwide operators, all coordinated by a central office acting as the system’s beating heart. They ensure pre-and post-sales support throughout the supply chain to the end consumer. This service is crucial, as it is the vital link between the product and those involved: the manufacturers, the dealers who present it to the end consumer, and the installers.

To enhance the Dierre brand, improve warranty and after-sales services, and streamline communication between the company and its network of technicians, the Technical Service is evolving towards a more fluid and efficient organizational model. A key factor in this transformation is the ongoing training of dealers and installers through the Dierre Academy and the addition of two new coordinators to improve communication between the company and the Technical Service network. Sergio Masè and Valerio Morichini are leading this complex organization and have extensive security experience. We interviewed them for their insights on the current state and the challenges ahead.

Technical Service by the Numbers

Founded in 2005, the Technical Service was created to enhance the purchasing experience and provide prompt, efficient solutions to any aftermarket issues. After an initial evaluation by four in-house operators, reports are forwarded to local technicians. Over time, the service has grown and become more structured, and today, it is ready for a further leap in quality.

“For a product like ours, technical aspects are critical,” says Liborio Arena, Dierre’s Quality Manager. “Addressing these issues holistically, rather than in isolated silos, and maintaining constant communication with production and quality control enables us to improve production flows continuously. This approach allows us to implement preventive and corrective measures to avoid repeating the same problems in the future.”

2005: The Year TS Was Established

45 Technicians Across Italy

24/7 Service: Available Around the Clock, Including Weekends, with a Fast-Track Procedure for Emergencies

When does a technician’s work begin?

“Right from the start, during the design phase, we conduct risk analysis and develop appropriate countermeasures tailored to the client’s needs. And most importantly, the work never truly ends! We’re available 24/7, but just as crucial is the continuous training and updating of everyone involved. Today, Technical Service is in its second iteration, and we’re preparing to launch version 3.0.”

What goals have you set?

“We aim to standardize the level of service across all regions of Italy, striving for excellence and eliminating territorial disparities. To achieve this, we will streamline our procedures further and introduce a modular training program focused on enhancing problem-solving skills for all operators. Additionally, we are bringing in two new coordinators—experienced locksmiths—who will constantly communicate with the technician team to improve coordination with the central office.”

What are the most common requests you receive from customers today?

“Requests vary from integrating existing locking systems with home automation, access control, intrusion detection, and video surveillance systems to upgrading security on older doors and performing routine maintenance. Many overlook that doors and safes, like all mechanical devices, require regular, extraordinary, and scheduled maintenance.”

Can you give some examples?

“A typical example of scheduled maintenance is cleaning and lubricating the lock and locking mechanism (including the lock, diverters, and cylinder). Doing this as part of a maintenance contract is more cost-effective and helps avoid emergencies. For extraordinary cases, we might be called to unlock a jammed armored door after a break-in attempt or due to negligence. If you don’t address a door that doesn’t close properly because of poor installation, it can drastically reduce the lifespan of the cylinder and lock.

This is why it’s crucial to have a reliable technical consultant who can transparently maintain active and passive security systems in the home. Too often, people feel secure just because they ‘have a security door,’ without realizing that it may be 20 years old and has never been updated. Unfortunately, there is a lack of awareness around security. Our daily mission is to spread accurate information, but for communication to be truly effective, everyone in the supply chain—company, technical department, and dealers—must speak with one voice.”

Installation of a technical product like a security door is crucial. What goals have you set for yourself?

“Ongoing training for installers and the entire sales force is a key part of our improvement plan. As we often say, service is just as important—if not more—than the product itself!

To put it in relatable terms, installation is the final result of what ingredients are needed by a chef in a restaurant. You can buy the best ingredients, but if the chef lacks skill, the dining experience will be average, and the restaurant will never earn a star. Many installers fail to understand this concept. Dierre offers cutting-edge technology, but for it to be the right choice, the installation must be done with expertise. Only then does the product’s true value emerge, completing the entire experience.”

Would you like additional information? Contact us!

Share this article

Back